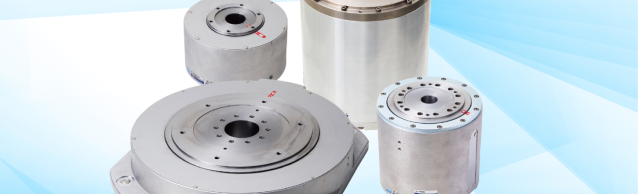

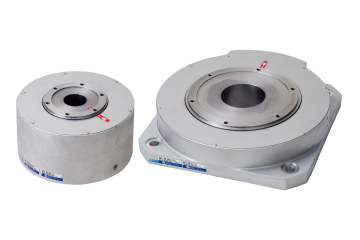

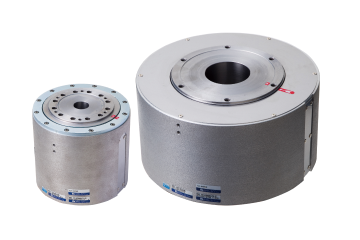

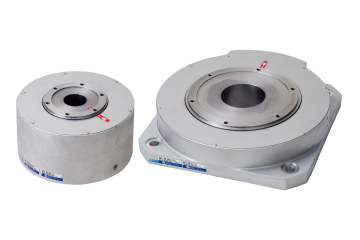

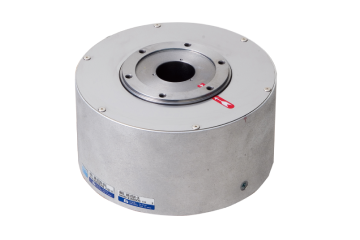

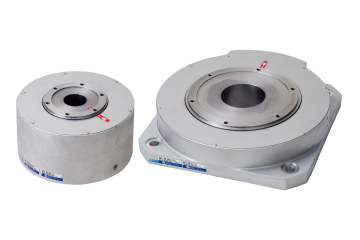

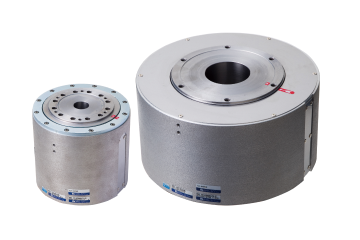

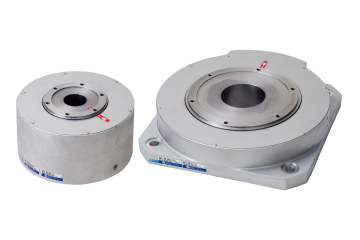

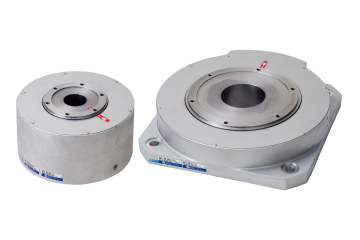

Lineup list of the τDISC and τiD roll direct drive motor drives

General-purpose index drive / winding drive

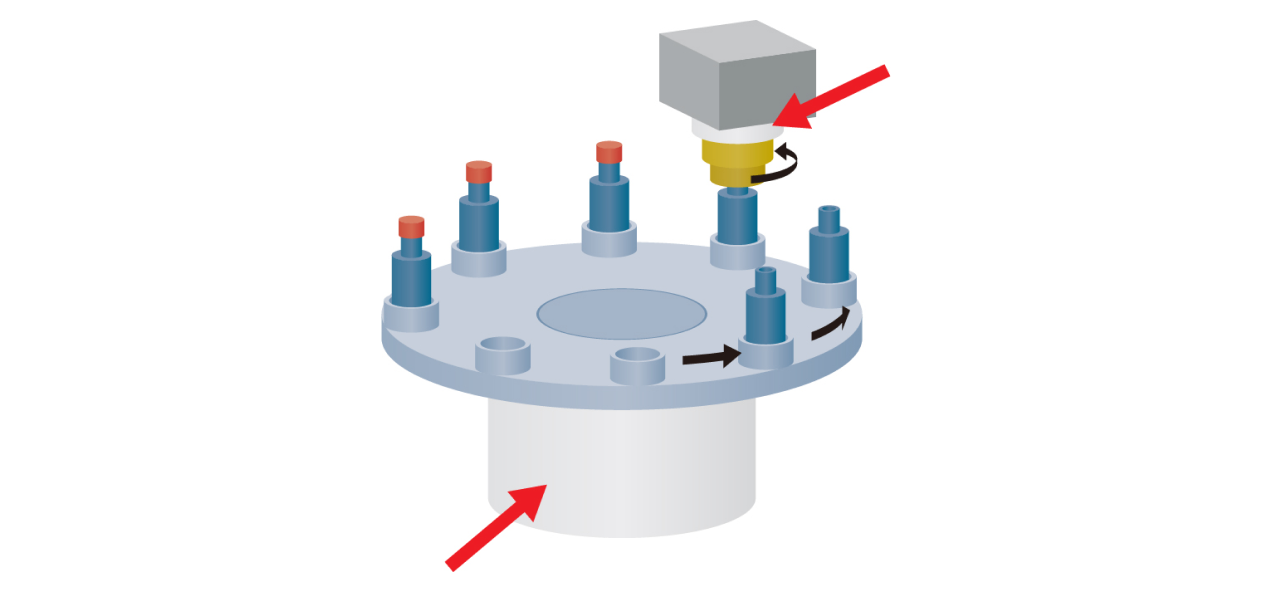

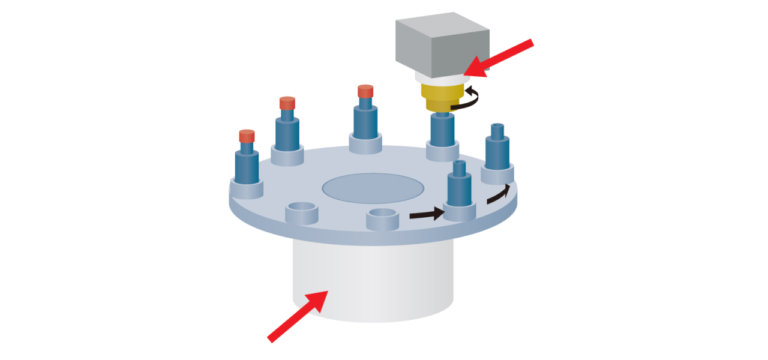

Capping machines and index machines

Benefits of using the direct drive

[Capping machine]

- Quality enhanced by improved output torque reproducibility

- Reduction in the number of retries (reduced machine takt time)

- Simplification of the machine enabled by the gearless, hollow structure

[Index machine]

- Flexible indexing angle setting

- Shorter positioning time (reduced machine takt time)

- Increased absolute positioning accuracy

- Simplification of the machine, increase in energy efficiency, quiet performance, enhancement in maintainability, all enabled by the gearless structure

- Effective use of hollow holes

Recommended direct drive

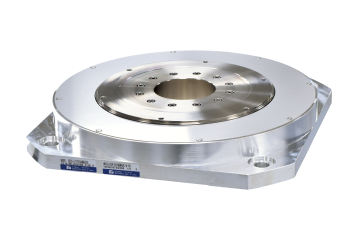

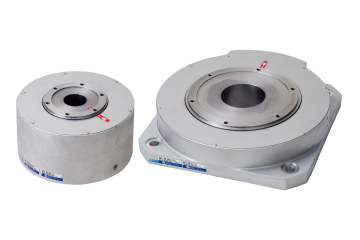

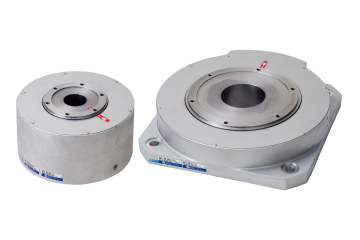

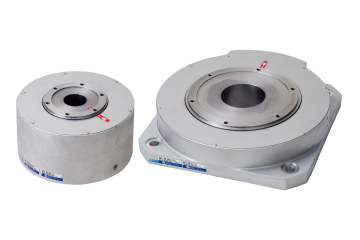

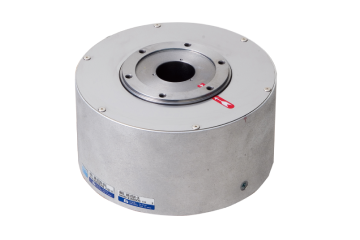

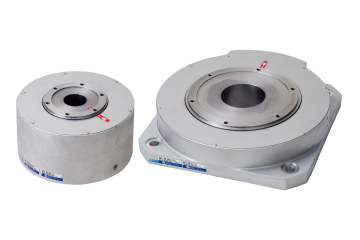

τDISC ND-s Series: Rated torque 3.4 to 500 N∙m

- Space saving and cost balance

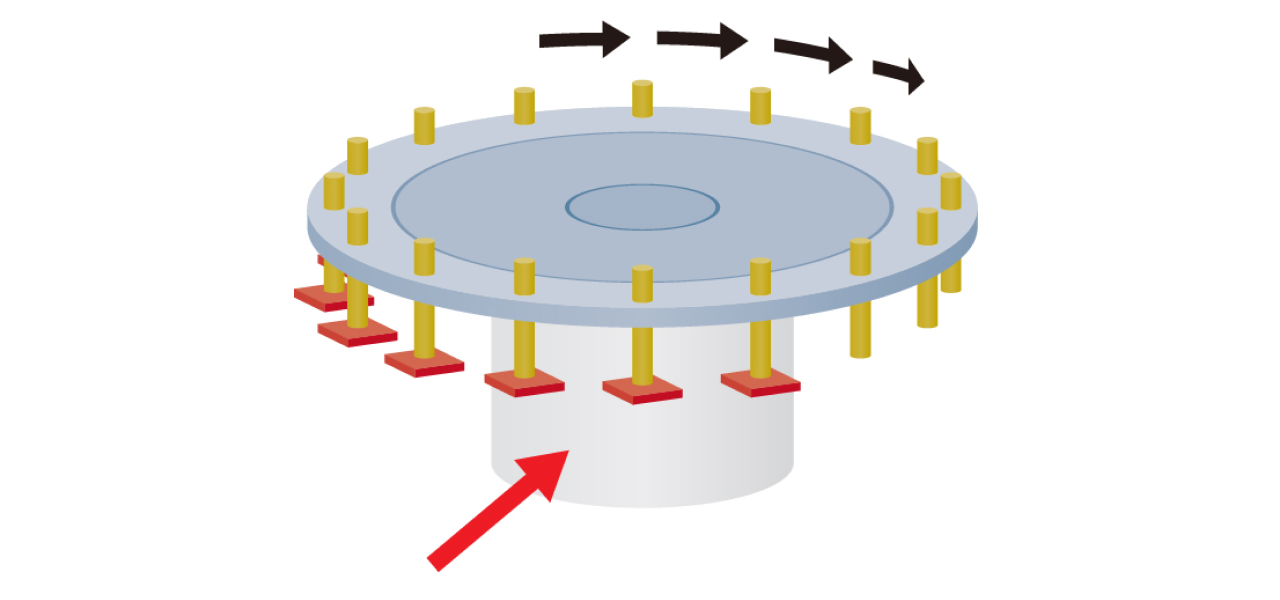

High-speed index drive

Processing and inspection of electronic parts, taping devices, sorters

Benefits of using the direct drive

- Positioning time reduced by providing lower inertia and high rigidity (high response) for the torque transmission path to the rotated object

- Highly accurate index positioning enabled by the reduction in angular transmission error and the increase in absolute positioning accuracy

- Simplification of the machine, increase in energy efficiency, quiet performance, enhancement in maintainability, all enabled by the gearless structure

- Effective use of hollow holes

Recommended direct drive

τDISC HD-s Series: Rated torque 27 to 68 N∙m

- High response

τDISC ND-s Series: Rated torque 3.4 to 500 N∙m

- Space saving and cost balance

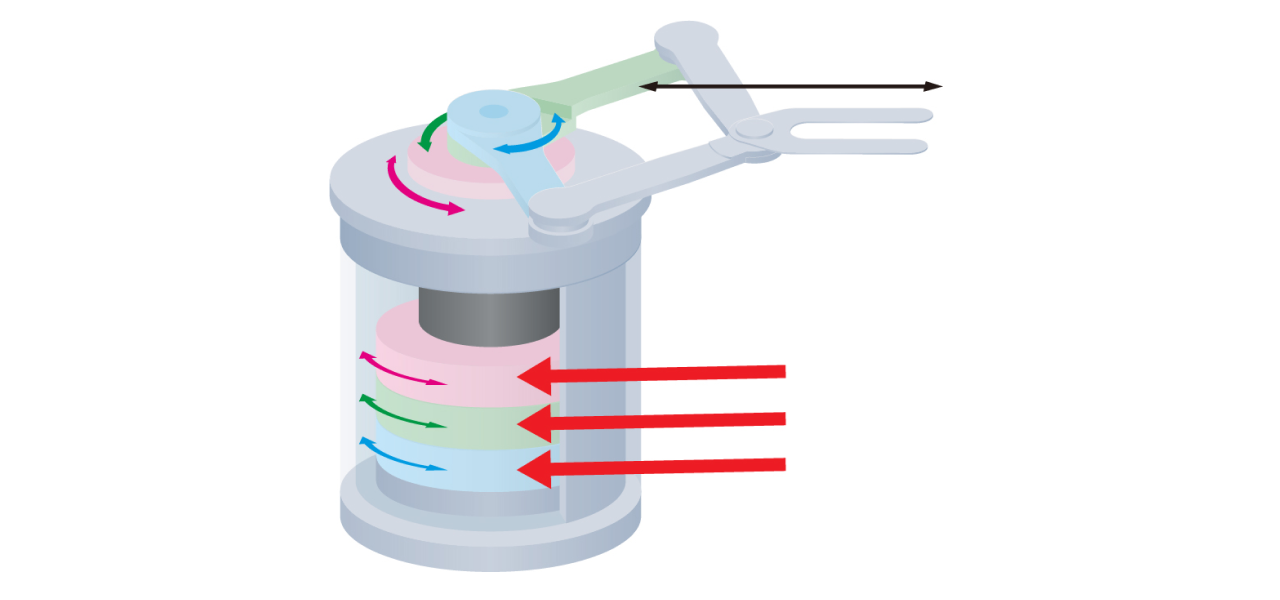

Transport robot drive

Wafer transport robots

Features and benefits of using the direct drive

- Simplification of the machine, increase in energy efficiency, quiet performance, enhancement in maintainability, all enabled by the gearless structure

- Effective use of hollow holes

Recommended direct drive

τDISC ND-u Series: Rated torque 11.5 to 35 N∙m

- Thin and space-saving

τDISC ND-s Series: Rated torque 3.4 to 500 N∙m

- Cost balance

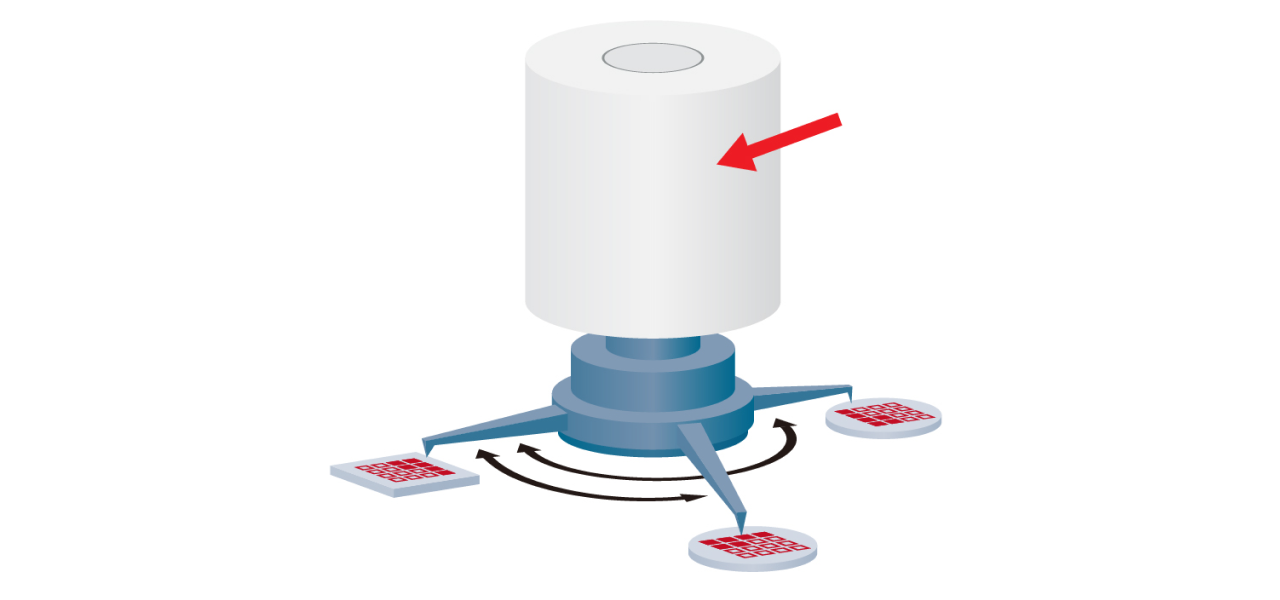

High-speed pick-and-place drive

Processing and inspection of electronic parts, taping devices, sorters

Features and benefits of using the direct drive

- Positioning time reduced by providing lower inertia and high rigidity (high response) for the torque transmission path to the rotated object

- Highly accurate reciprocating motion enabled by the backlash-less driving and increased repeated positioning accuracy

- Simplification of the machine, increase in energy efficiency, quiet performance, enhancement in maintainability, all enabled by the gearless structure

- Effective use of hollow holes

Recommended direct drive

τDISC ND-s HS Series: Rated torque 8 to 24 N∙m

- High-speed positioning

τDISC ND-s Series: Rated torque 3.4 to 500 N∙m

- Cost balance

Continuous rotation drive

Surface polishing machines and chamfering machines for the FPD and semiconductor industries

Features and benefits of using the direct drive

- Improvement in torque, speed, and position accuracy during variable speed rotation and continuous constant speed rotation

- Simplification of the machine, increase in energy efficiency, quiet performance, enhancement in maintainability, all enabled by the gearless structure

- Effective use of hollow holes

Recommended direct drive

τDISC ND-s Series: Rated torque 3.4 to 500 N∙m

- Space saving and cost balance

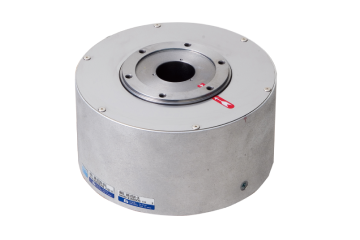

τDISC DD-s Series: Rated torque 10 to 2000 N∙m

- High rigidity and high accuracy

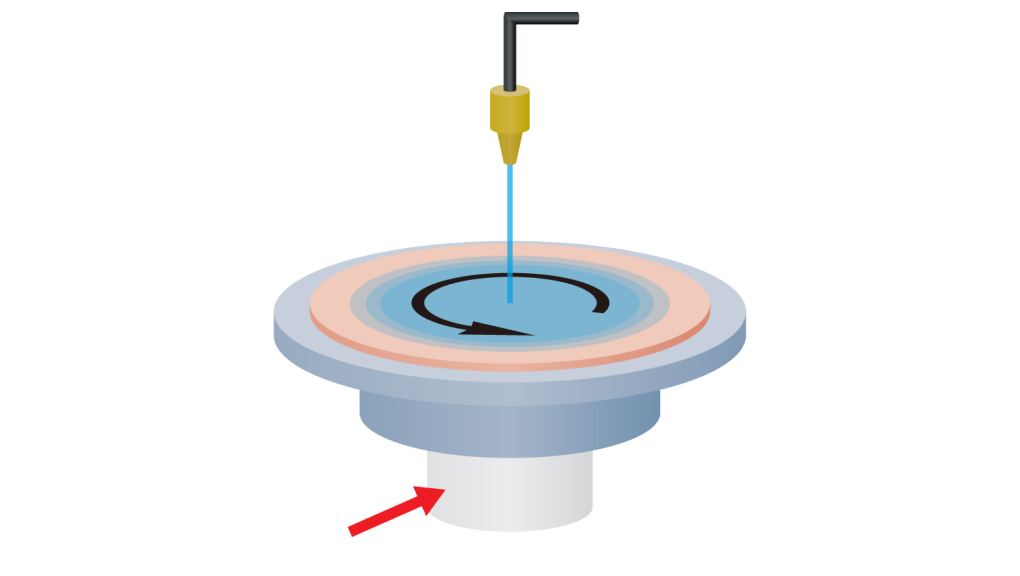

Spin drive

Cleaning of liquid crystal substrates and semiconductor wafers and chemical coating

Features and benefits of using the direct drive

- Reduction in acceleration/deceleration time (machine takt time), improvement in speed stability, and post-acceleration/deceleration behavior stability enabled by providing high rigidity (high response) for the torque transmission path to the rotated object

- Simplification of the machine, increase in energy efficiency, quiet performance, enhancement in maintainability, all enabled by the gearless structure

- Effective use of hollow holes

Recommended direct drive

τDISC ND-s HS Series: Rated torque 8 to 24 N∙m

- High-speed rotation

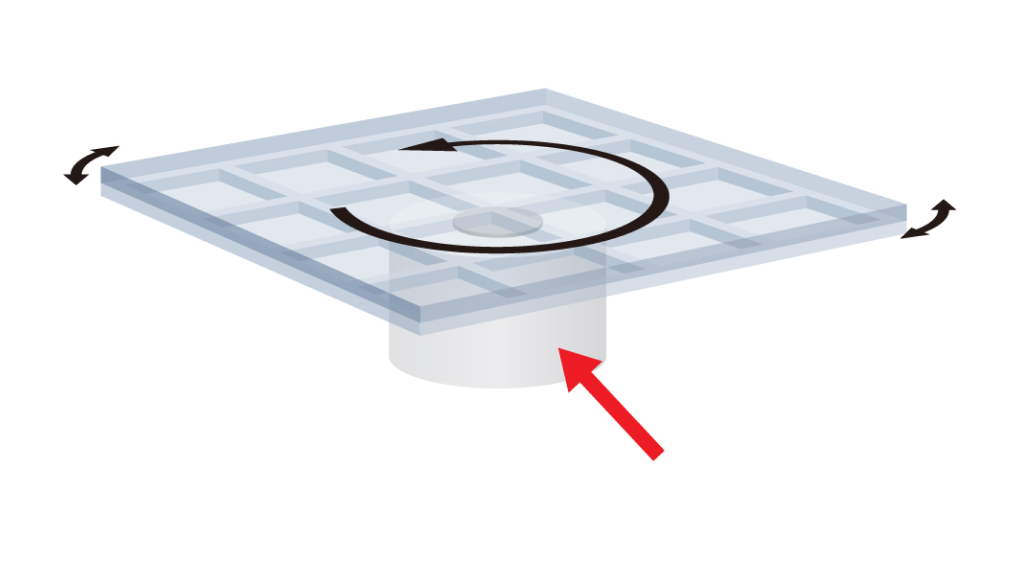

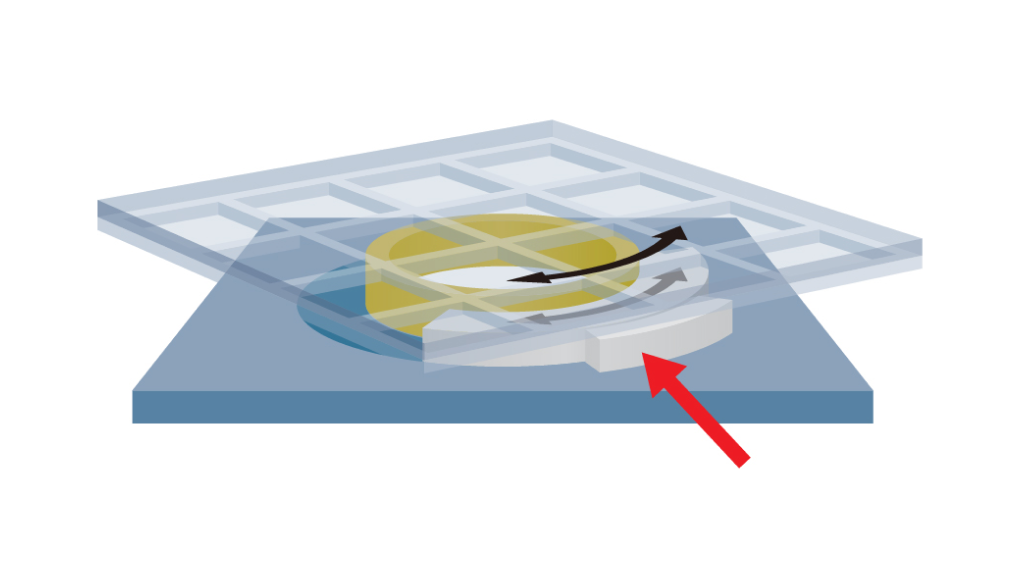

Table drive

Processing of mechanical and electronic parts and inspection machines

Features and benefits of using the direct drive

- Improvement in speed stability and reduction in variation of steady-state deviation during motor rotation by providing high rigidity (high response) for the torque transmission path to the rotated object

- Highly accurate alignment and reciprocating motion enabled by the backlash-less driving and increased repeated positioning accuracy

- Highly accurate index positioning enabled by the reduction in angular transmission error and the increase in absolute positioning accuracy

- Simplification of the machine, increase in energy efficiency, quiet performance, enhancement in maintainability, all enabled by the gearless structure

- Effective use of hollow holes

Recommended direct drive

τDISC ND-s Series: Rated torque 3.4 to 500 N∙m

- Space saving and cost balance

τDISC DD-s Series: Rated torque 10 to 2000 N∙m

- High rigidity and high accuracy

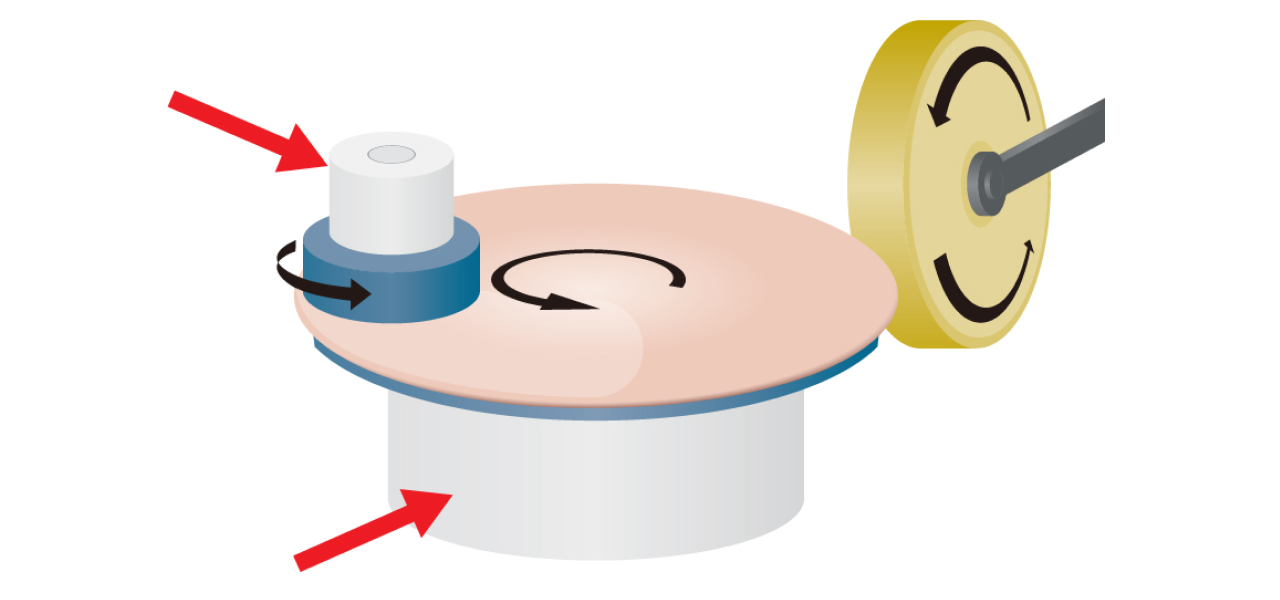

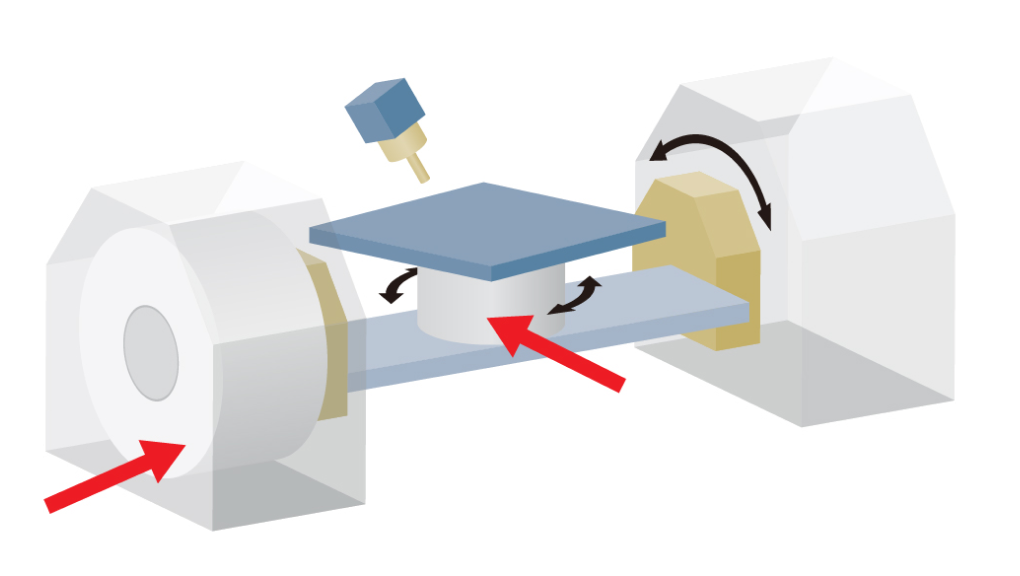

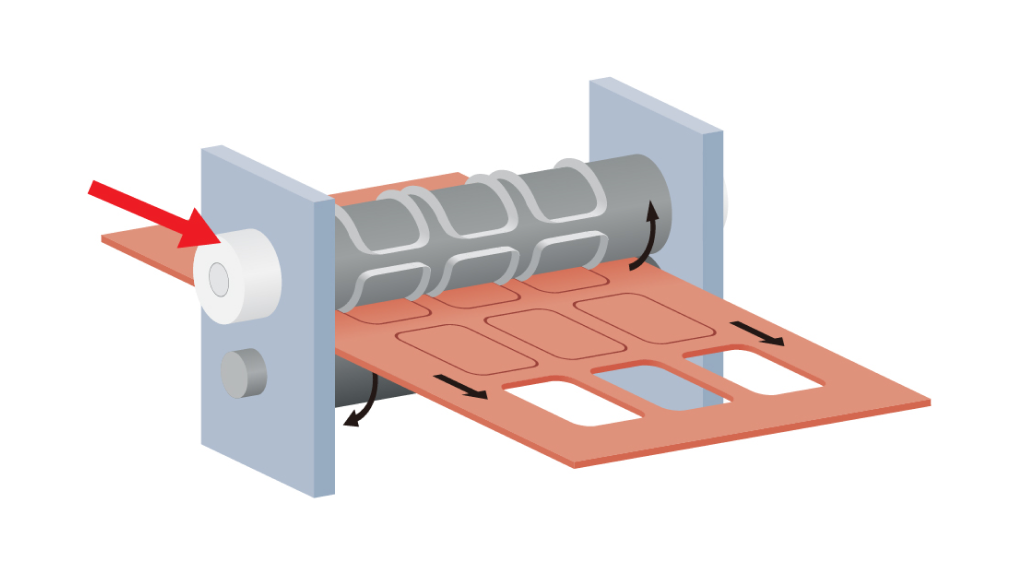

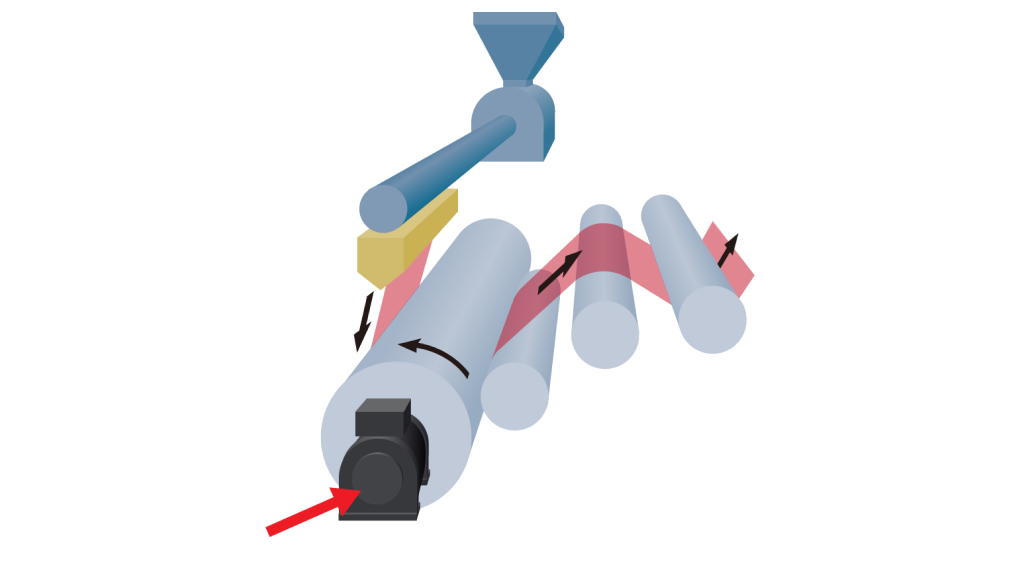

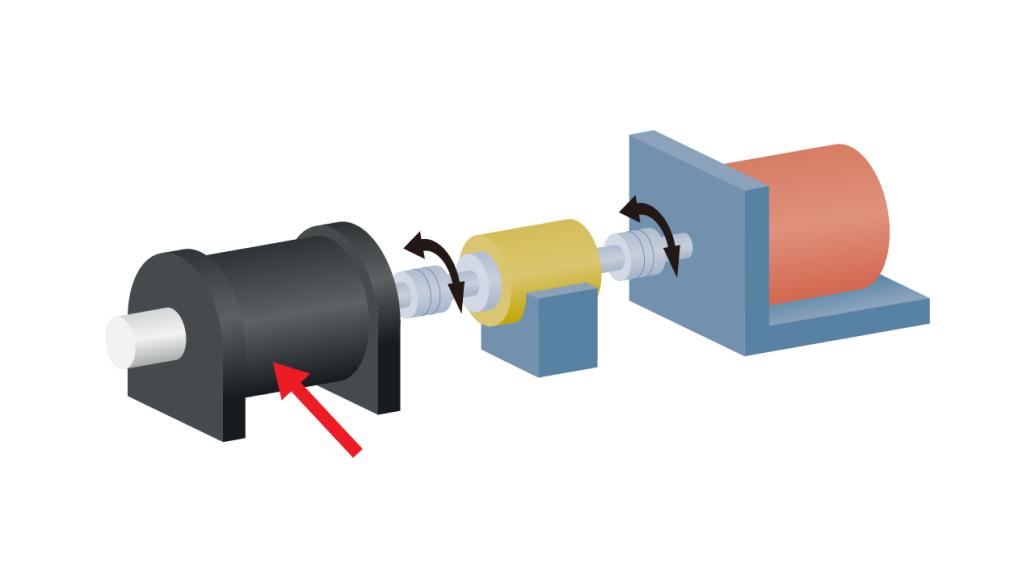

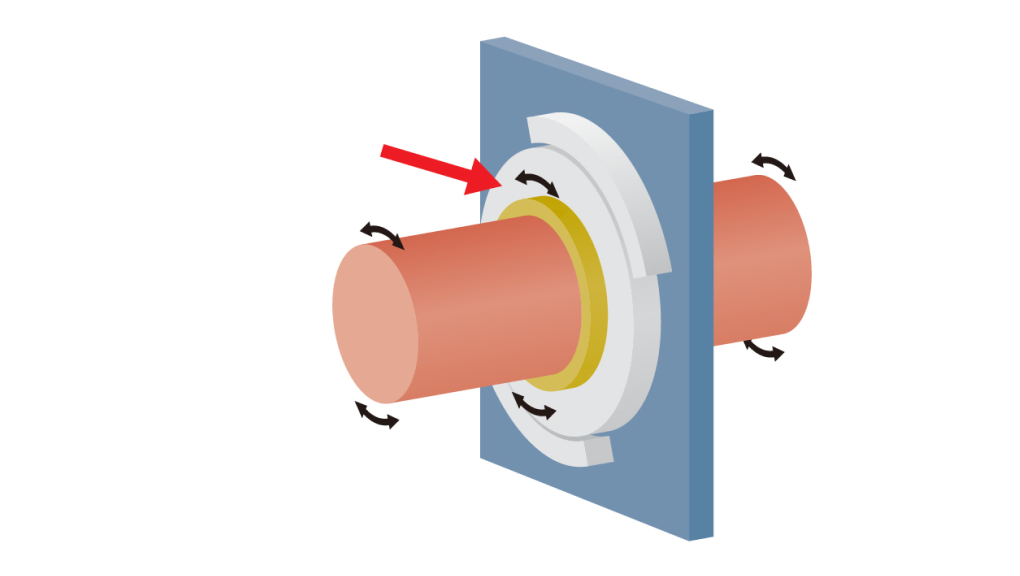

Roll drive

Paper and film rotary processing machines and metal, paper, and film roll feeders

Features and benefits of using the direct drive

- Improvement in speed stability and reduction in variation of steady-state deviation during motor rotation by providing high rigidity (high response) for the torque transmission path to the rotated object

- Simplification of the machine, increase in energy efficiency, quiet performance, enhancement in maintainability, all enabled by the gearless structure

- Effective use of hollow holes

Recommended direct drive

τDISC ND-s Series: Rated torque 3.4 to 500 N∙m

- Space saving and cost balance

τDISC ND-s HS Series: Rated torque 8 to 24 N∙m

- High-speed rotation

τDISC HD-s Series: Rated torque 27 to 68 N∙m

- High response

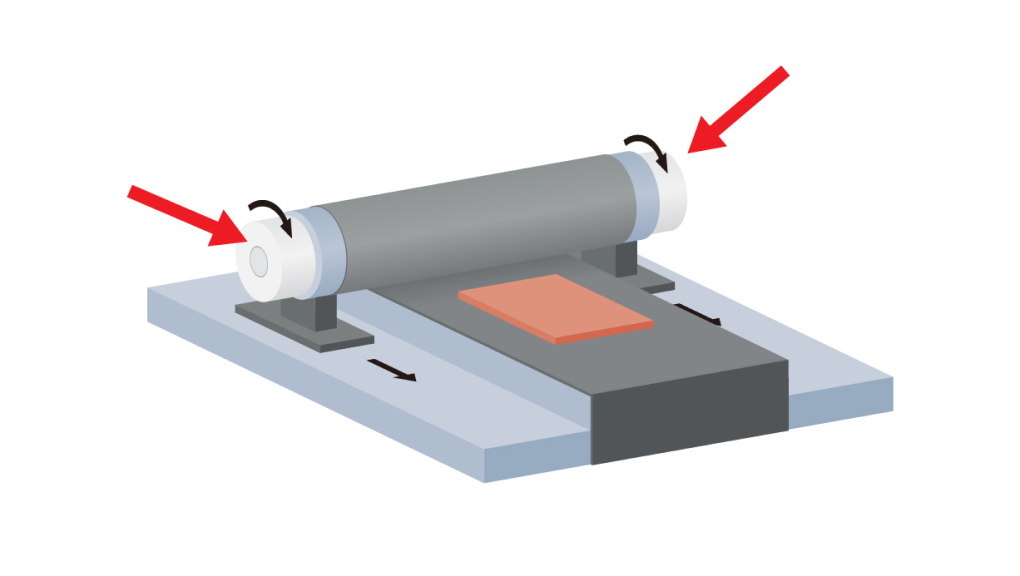

High-accuracy roll drive + gantry synchronization drive

PE printers and roll coating machines

Features and benefits of using the direct drive

- Improvement in speed stability and reduction in variation of steady-state deviation during motor rotation by providing high rigidity (high response) for the torque transmission path to the rotated object

- Process performance enhanced by the reduction in angular transmission error and the increase in absolute positioning accuracy

- Simplification of the machine, increase in energy efficiency, quiet performance, enhancement in maintainability, all enabled by the gearless structure

- Effective use of hollow holes

Recommended direct drive

τDISC ND-s Series: Rated torque 3.4 to 500 N∙m

- Space saving and cost balance

τDISC DD-s Series: Rated torque 10 to 2000 N∙m

- High rigidity and high accuracy

Recommended control

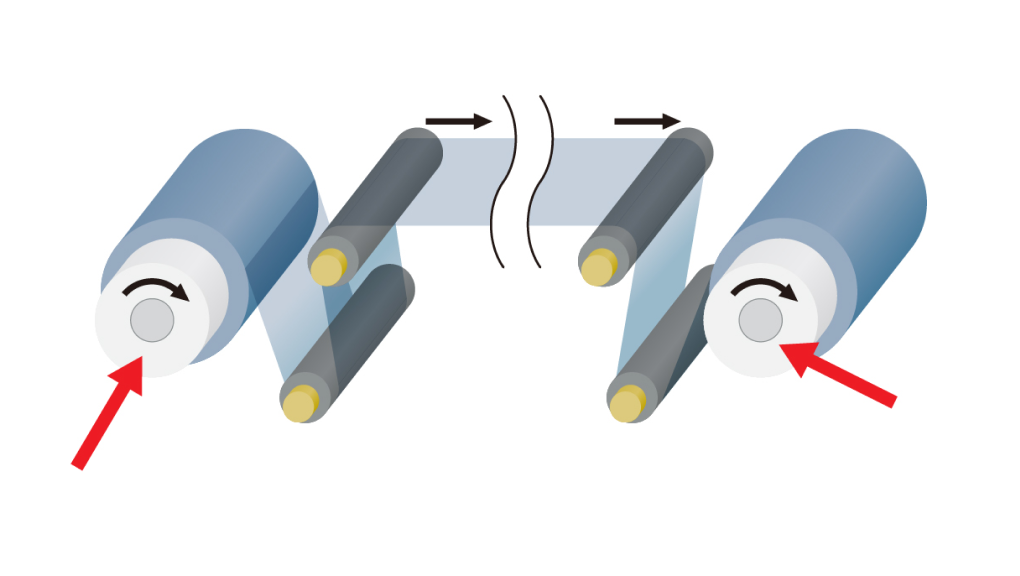

Winding and unwinding drive

Powder clutch (brake) replacement coating, lamination, and surface inspection in roll-to-roll equipment for the paper and film industries

Features and benefits of using the direct drive

- Stable operation and output command quantification using servo control

- Improvement in speed stability and reduction in variation of steady-state deviation during motor rotation by providing high rigidity (high response) for the torque transmission path to the rotated object

- Simplification of the machine, increase in energy efficiency, quiet performance, enhancement in maintainability, all enabled by the gearless structure

- Effective use of hollow holes

- Motion network-enabled driver used to integrate with the control systems of other AC servo motors

Recommended direct drive

τDISC ND-s Series: Rated torque 3.4 to 500 N∙m

- Space saving and cost balance

τDISC ND-s HS Series: Rated torque 8 to 24 N∙m

- High-speed rotation

τDISC HD-s Series: Rated torque 27 to 68 N∙m

- High response

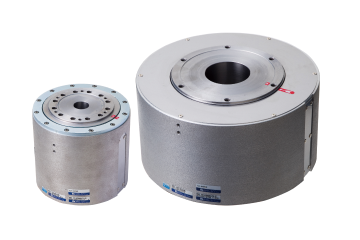

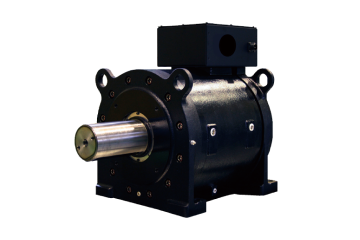

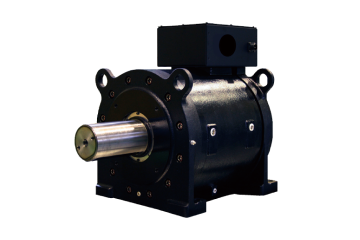

Cast roll drive

Replacement of a speed reducer-equipped motor in coating equipment

Features and benefits of using the direct drive

- Quality enhanced by high-accuracy speed stability using servo control

- Gearless, direct drive ensures safe quick acceleration, deceleration, and stop.

- Simplification of the machine, increase in energy efficiency, quiet performance, enhancement in maintainability, all enabled by the gearless structure

Recommended direct drive

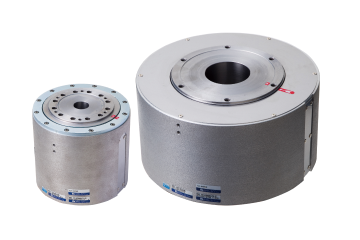

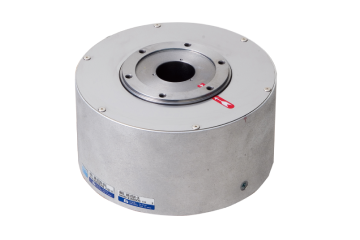

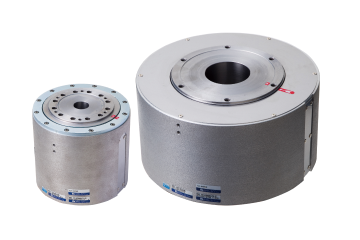

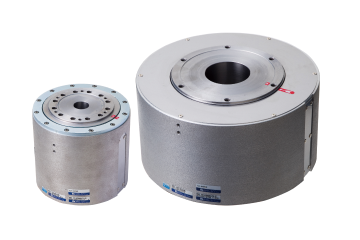

τiD roll (water cooling): Rated torque 550 to 7500 N∙m

- Large-torque cylinder type

τiD roll (fan cooling): Rated torque 150 to 5200 N∙m

- Large-torque cylinder type

Tester drive and continuous regenerative drive

Proposal for replacement of a speed reducer-equipped motor or hydraulic motor

Torque testers, material testers, durability testers, etc.

Features and benefits of using the direct drive

- Gearless, direct drive ensures high response.

- Space-saving and improved quiet performance

- Environmental friendliness and safety enhanced by non-hydraulic drive

- Torque accuracy and speed accuracy increased by the multi-pole structure and cogging and torque ripple reduction for customized bearings

- Linearization of cam-type straight line motion

- The lineup includes a power regeneration type servo drive.

Recommended direct drive

τiD roll (water cooling): Rated torque 550 to 7500 N∙m

- Large-torque cylinder type

τiD roll (fan cooling): Rated torque 150 to 5200 N∙m

- Large-torque cylinder type

τDISC HD-s Series: Rated torque 27 to 68 N∙m

- High response

τDISC DD-s Series: Rated torque 10 to 2000 N∙m

- High torque and high rigidity

Large inertia load pivoting drive

Processing and inspection equipment for liquid crystal substrates

Features and benefits of using the direct drive

- Stable operation ensured by suppressing hunting oscillation even at large inertia load

- Highly accurate alignment and reciprocating motion enabled by the backlash-less driving and increased repeated positioning accuracy

- Highly accurate index positioning enabled by the reduction in angular transmission error and the increase in absolute positioning accuracy

- Simplification of the machine, increase in energy efficiency, quiet performance, enhancement in maintainability, all enabled by the gearless structure

- Effective use of hollow holes

Recommended direct drive

τDISC ND-s Series: Rated torque 3.4 to 500 N∙m

- Space saving and cost balance

τDISC DD-s Series: Rated torque 10 to 2000 N∙m

- High rigidity and high accuracy

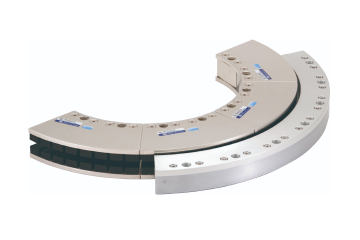

Arc type circumference drive

FPD, wafer pivoting, alignment equipment, inspection machines, etc.

Features and benefits of using the direct drive

- High-accuracy positioning enabled by position detection on the periphery

- Cost reduced by installing magnet bases only at angles where motion is required

- Maintainability increased by resistance to aging

- Effective use of hollow holes

Recommended direct drive

Large-diameter rotation drive

Surface inspection machines, transparent stages, etc.

Features and benefits of using the direct drive

- Stable operation achieved across a range of speeds from low speed to high speed by the coreless, cogging-free drive

- Simple structure, space-saving, low noise, low vibration

- Maintainability increased by resistance to aging

- Effective use of hollow holes

Recommended direct drive

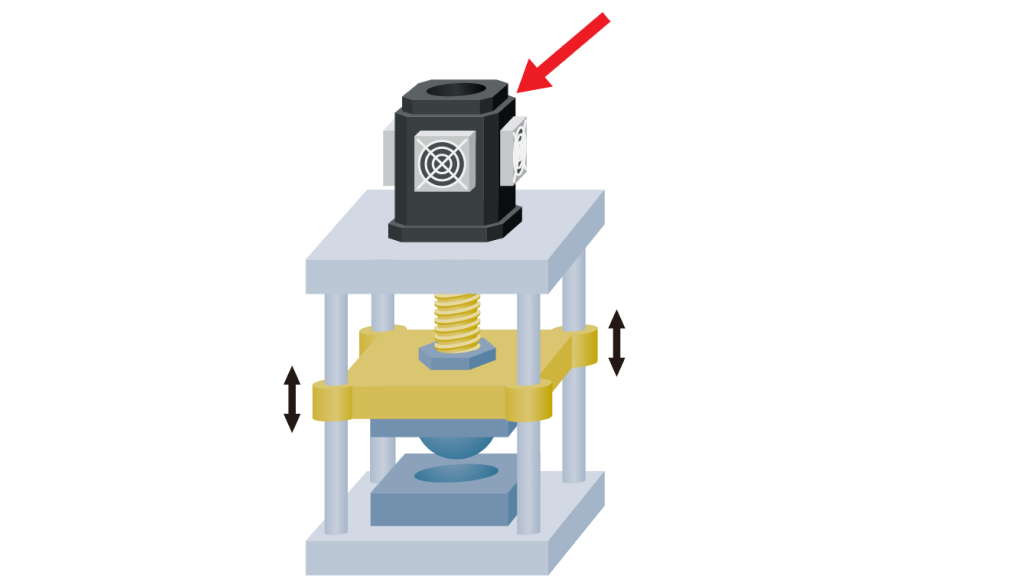

Ball screw drive

Molding machines, servo presses, etc.

Features and benefits of using the direct drive

- Gearless, direct drive ensures high response.

- Simplification of the machine enabled by the gearless, hollow structure

- Environmental friendliness and safety enhanced by non-hydraulic drive

Recommended direct drive

τiD roll (fan cooling): Rated torque 150 to 5200 N∙m

- Large-torque cylinder type

τDISC ND-s Series: Rated torque 3.4 to 500 N∙m

- Space saving and cost balance

τDISC DD-s Series: Rated torque 10 to 2000 N∙m

- High rigidity, high accuracy, high torque