A high-accuracy linear stage equipped with a linear servo motor. Combined with the servo control technology, the stage enables highly accurate control.

The linear stages of CKD NIKKI DENSO are designed in pursuit of stage structure rigidity, positioning accuracy and speed stability and travel smoothly with high accuracy. They achieve highly accurate representation of the motion required by the customer.

Increasingly more accurate linear stages for precision machining equipment

In FA equipment that can promote automation and labor saving, positioning mechanisms (stages) are often used. Particularly, stages for precision machining equipment, which is a type of FA equipment, are becoming increasingly more accurate, and positioning accuracy and speed stability are required during machining.

In the case of a laser beam machine, for example, positioning accuracy is crucial in meeting the requirement of creating holes within a pitch tolerance of 1 μm. Also, reducing speed fluctuations during the movement of a workpiece allows irradiation energy to be given evenly over the workpiece. Therefore, a low speed variation is vital in reducing laser irradiation unevenness.

We are developing linear stages in pursuit of positioning accuracy and speed stability in order to meet these high-level requirements.

Pursue greater positioning accuracy through improved support rigidity and travel accuracy and temperature management

Many typical XY stages employ a stack structure where two single-axis stages are merely stacked orthogonally. Since the support point of the upper axis base frame is narrow, the structure displacement caused by the change in the load position when the table slides become great, which is disadvantageous.

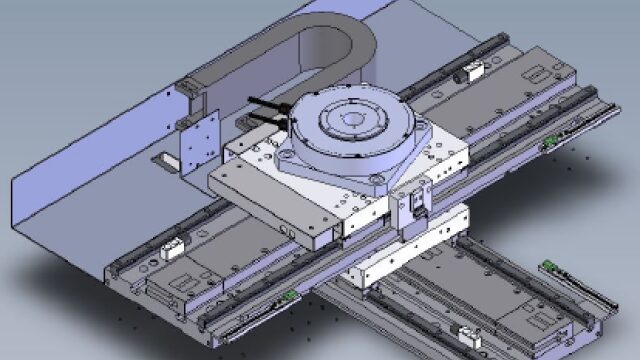

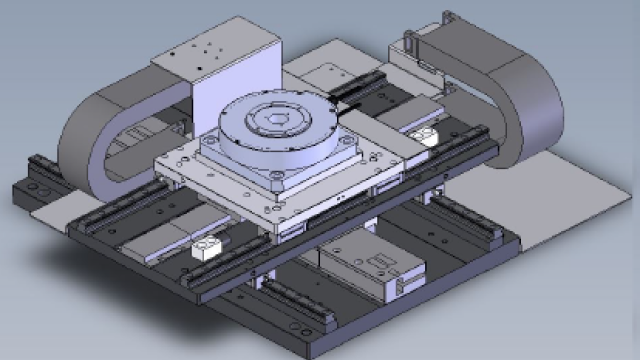

By contrast, our XY stage optimizes the support point of the upper axis base frame structure of XY, instead of stacking two identical single-axis stages, thereby reducing the structure displacement caused by the load position change when the table slides.

Difference in the XY stage support structure

● Typical XY stage

● Our XY stage

Improvement in table travel accuracy

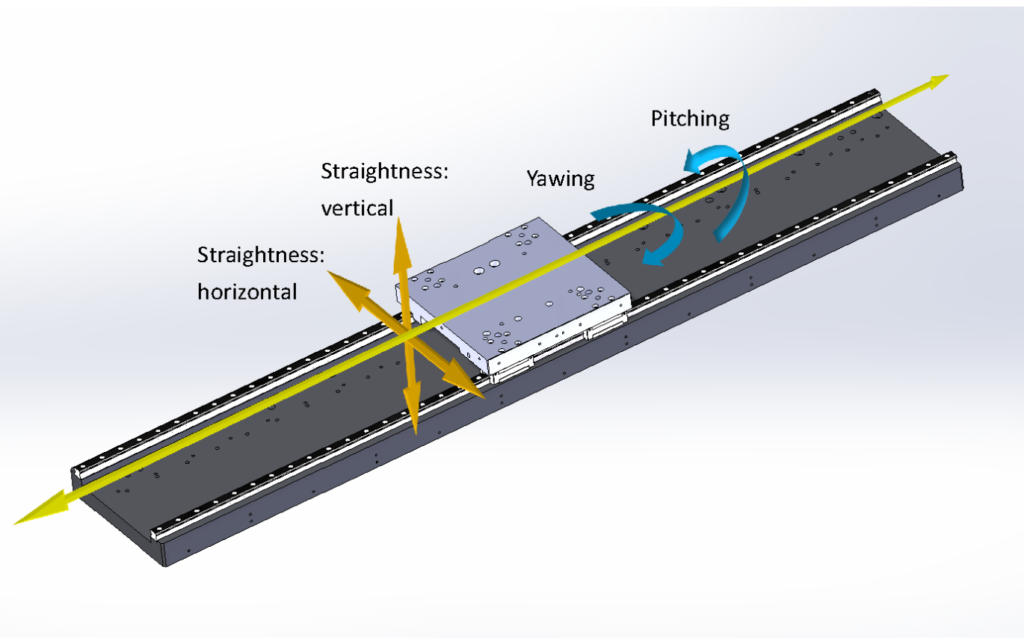

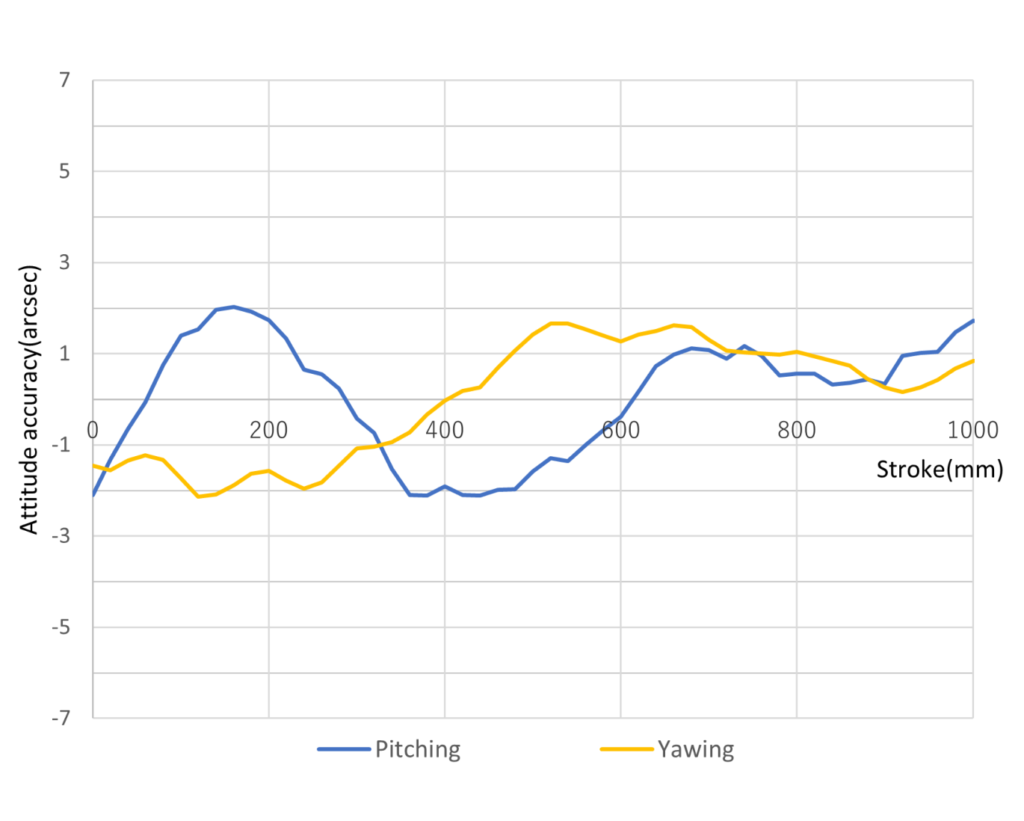

In high-precision machining, the attitude accuracy indicators of pitch and yaw, which represent the straightness of the travel trajectory of the moving table, the parallelism to the mounting surface, and the angle variation of the table surface, are vital.

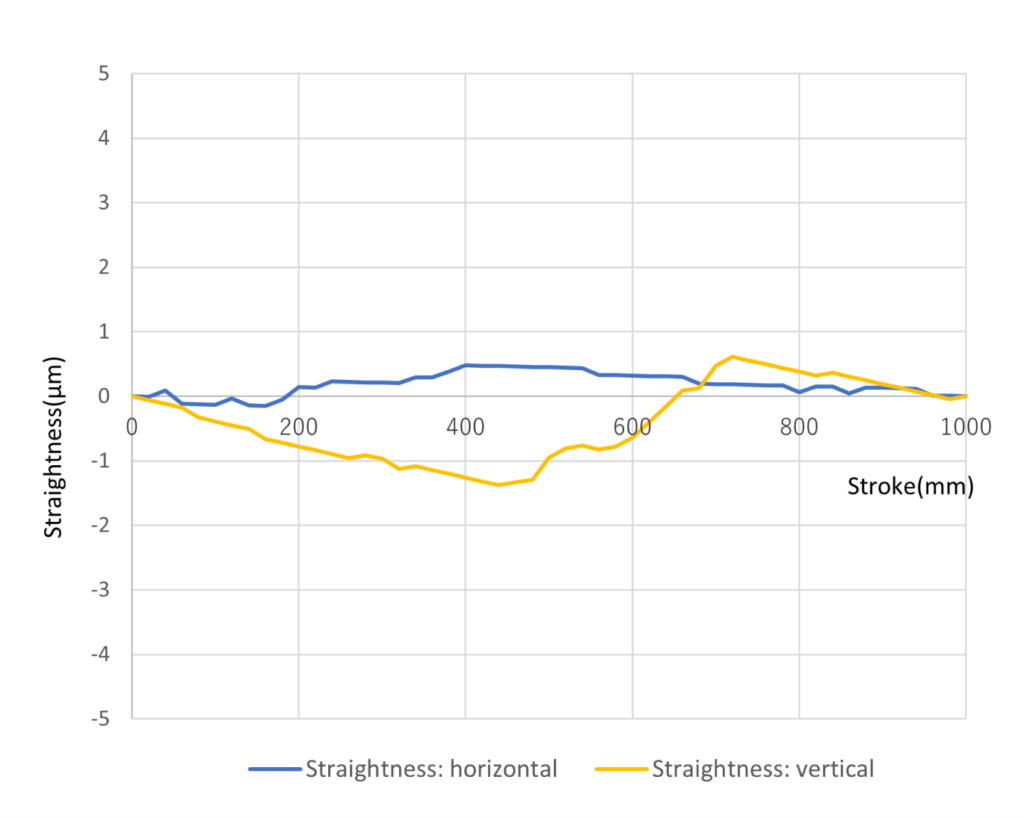

Our linear stage achieves improved travel accuracy by securing stage structure rigidity, optimizing the mounting position of the linear motion bearing and increasing the assembly accuracy of the linear motion bearing. For example, in a long stroke motion where the table width is 220 mm and the motion stroke is 1000 mm, the stage provides straightness of 2 μm or less and pitching and yawing attitude accuracy of 5 arcsec or less.

● Table straightness (horizontal and vertical directions)

● Table attitude accuracy (pitching and yawing)

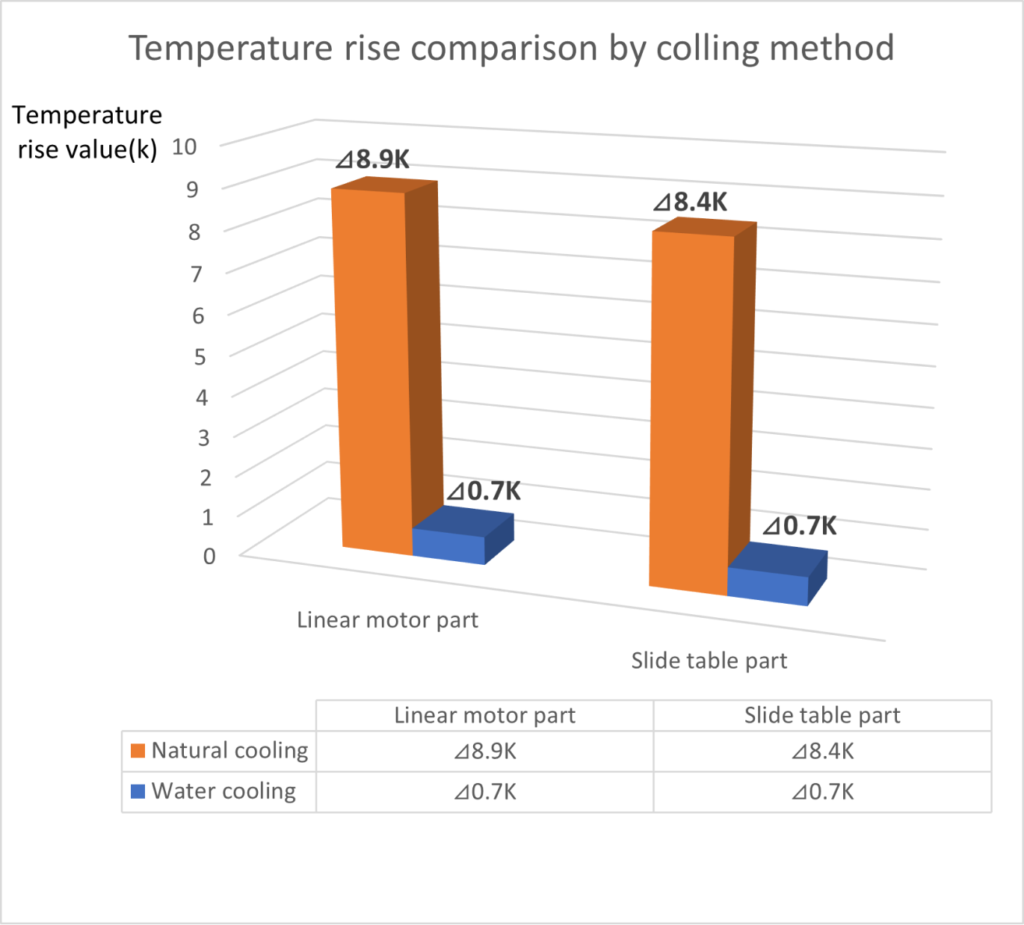

Suppression of temperature rises

Thermal expansion due to a temperature rise is also detrimental to ultra-high precision machining because it changes the positional accuracy. To address this problem, we have developed a water-cooled linear motor and our linear stage uses this motor.

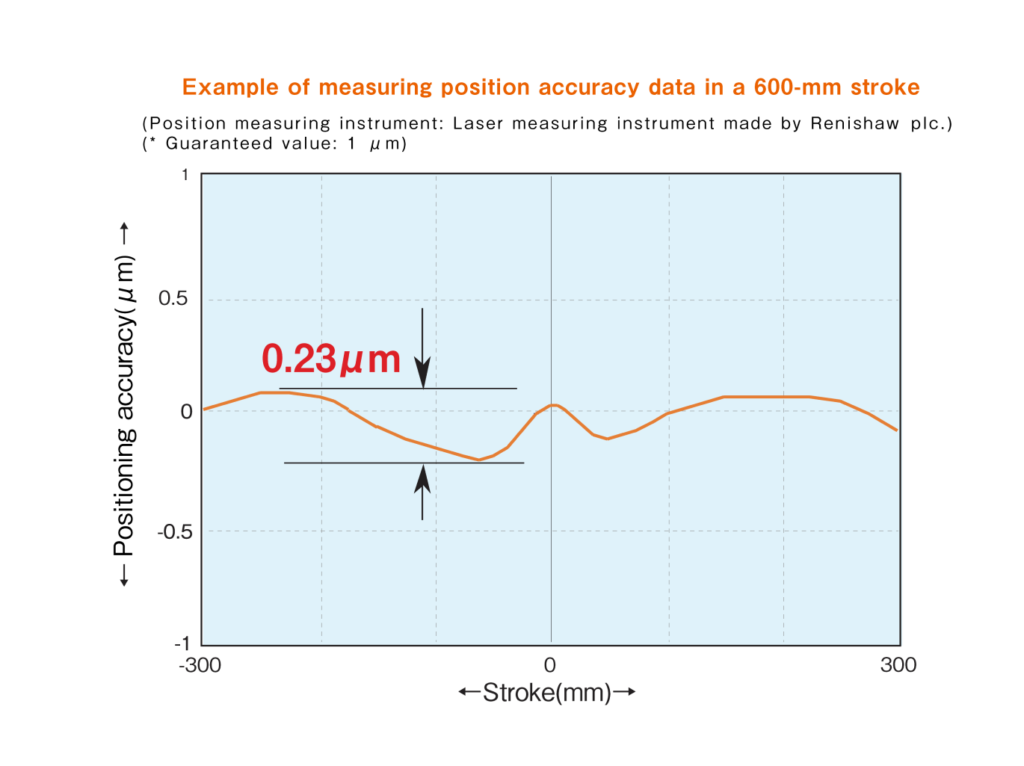

Positioning accuracy compensation function

The positioning accuracy of a stage is measured with a laser interferometric distance meter before shipment, and compensation is performed to achieve a positioning accuracy of 1 μm or less. Positioning accuracy compensation for a mounted stage is also supported.

Pursue better speed variation performance using control functions developed by leveraging the advantages of in-house development

Reduction in torque ripples by magnetic flux optimization and other means

Use of a coreless linear motor

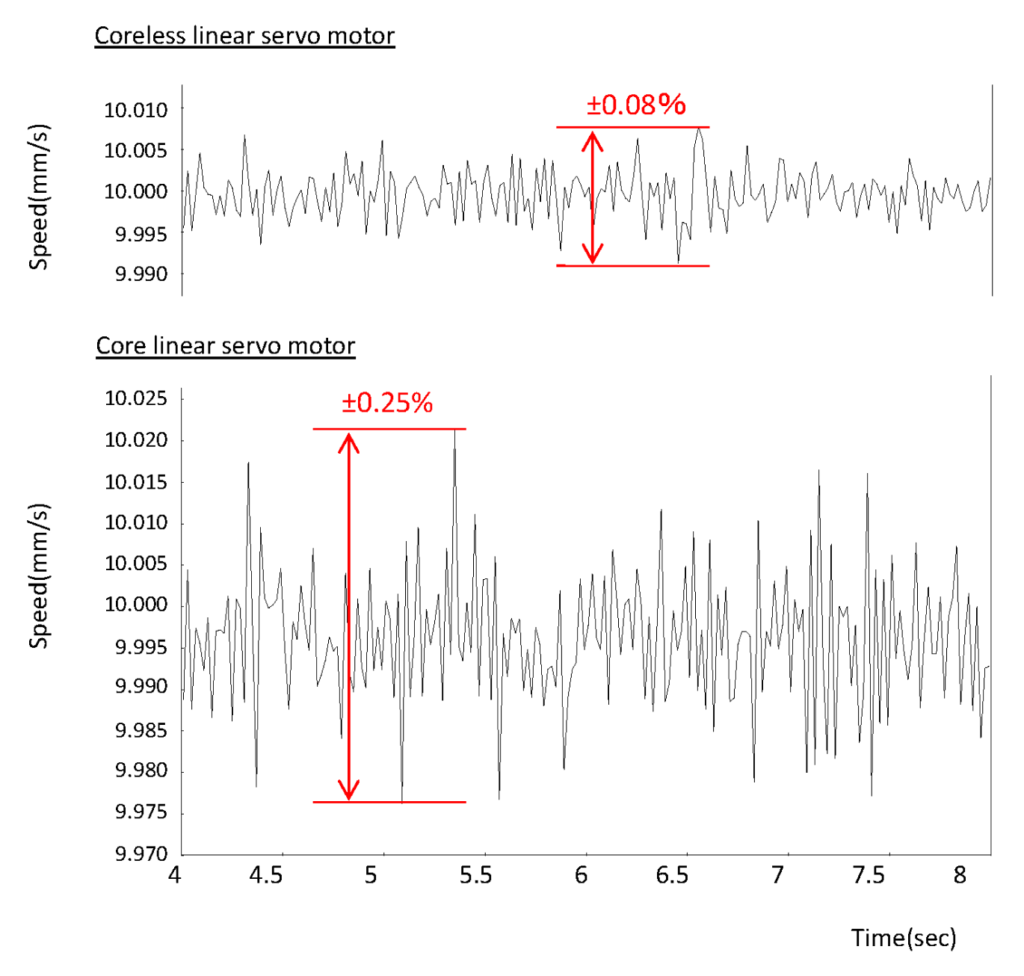

For example, when the speed is 10 mm/arcsec and the measurement sampling frequency is 50 Hz, the speed variation for a coreless linear motor is ±0.08%, compared to ±0.25% for a core linear motor.

Comparison of speed variation between coreless linear motor and core linear motor

Driver adjustment parameters for the servo driver to improve speed variation

By leveraging the advantages of in-house development, we offer additional control functions that are easy to build into the system, such as the torque ripple compensation function and feedback filter function.

Customization and other features make it possible for customers to readily use our linear stages

Our linear stages come standard with a cable carrier and are shipped with the gain tuned. This makes it possible for customers to readily use the stages, providing significant savings in the design and assembly processes on the customer side. In addition to the rich lineup of standard products, we cater to the need for customization, delivering a linear stage that’s just right for the customer’s equipment.

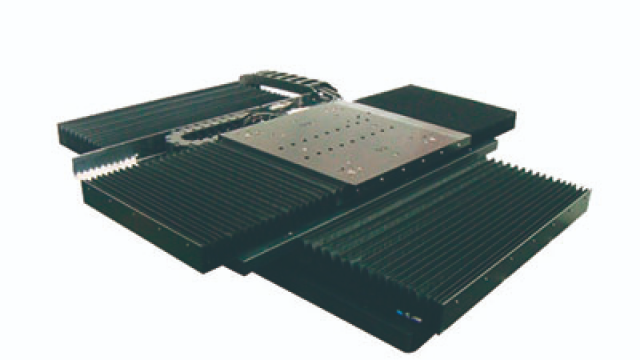

● Bellows specification

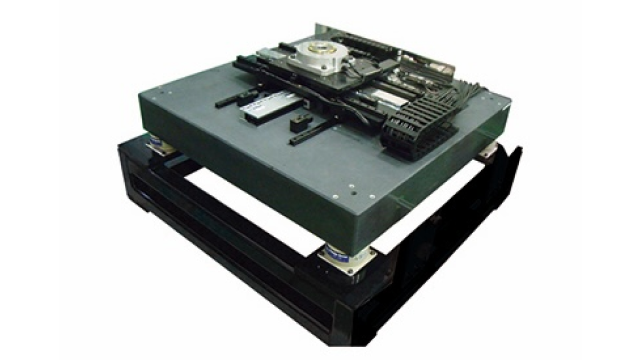

● XYθ specification (with our thin type DD motor)

● Stone surface plate with an anti-vibration table

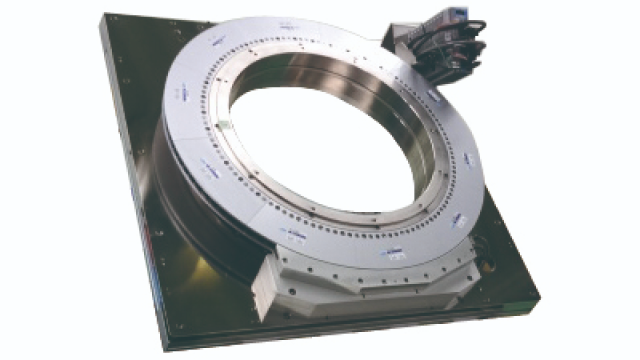

● Large-hollow diameter rotary stage (with an arc type linear motor)